Case Study

Background

The largest steel maker in Taiwan treats its wastewater to reusable standards using reverse osmosis to meet sustainable development goals. The wastewater reclamation facility has a capacity of 14,400 m³/day (3.8 MGD) and returns the treated water to its industrial process. A minimum qualification trial of up to six (6) months is required to become an approved membrane supplier for the water recycling process.

Qualification

LG BW 400 R G2, LG Chem’s highest rejection brackish water RO membrane with a new proprietary low differential

pressure feed spacer, was piloted in a full train along with a leading competitor’s low-fouling membrane element also

equipped with a low dP feed spacer. Both models were tested and evaluated according to the conditions and test

criteria listed below:

Operating Conditions:

- Flux: 15 lmh (8.8 gfd)

- Recovery rate: 60–70%

- Temperature range: 30–40 °C (86–104 °F)

Test Criteria:

- Performance recovery after clean-in-place (CIP)

- Energy consumption

- Stabilization of membrane performance

Low energy consumption and stable performance

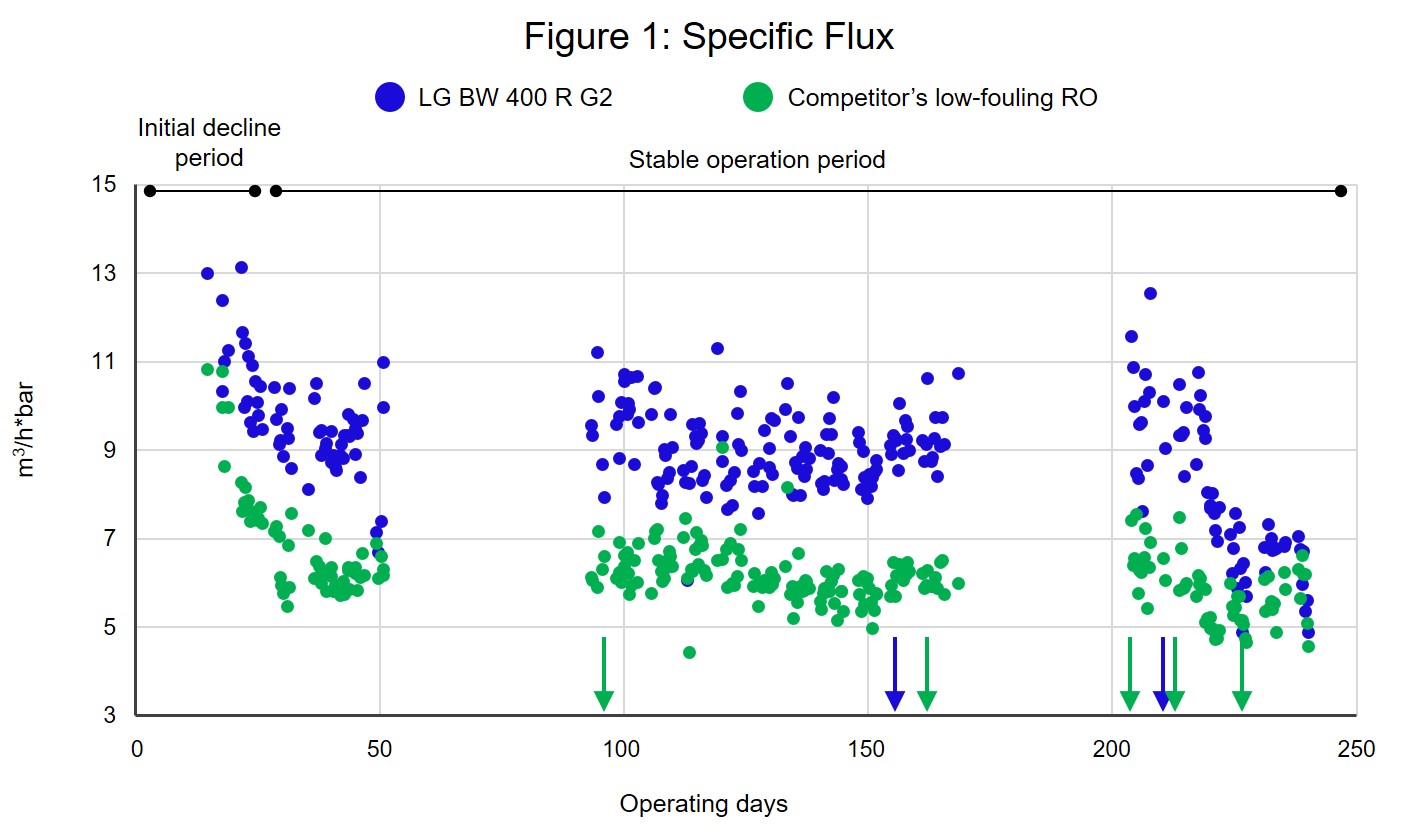

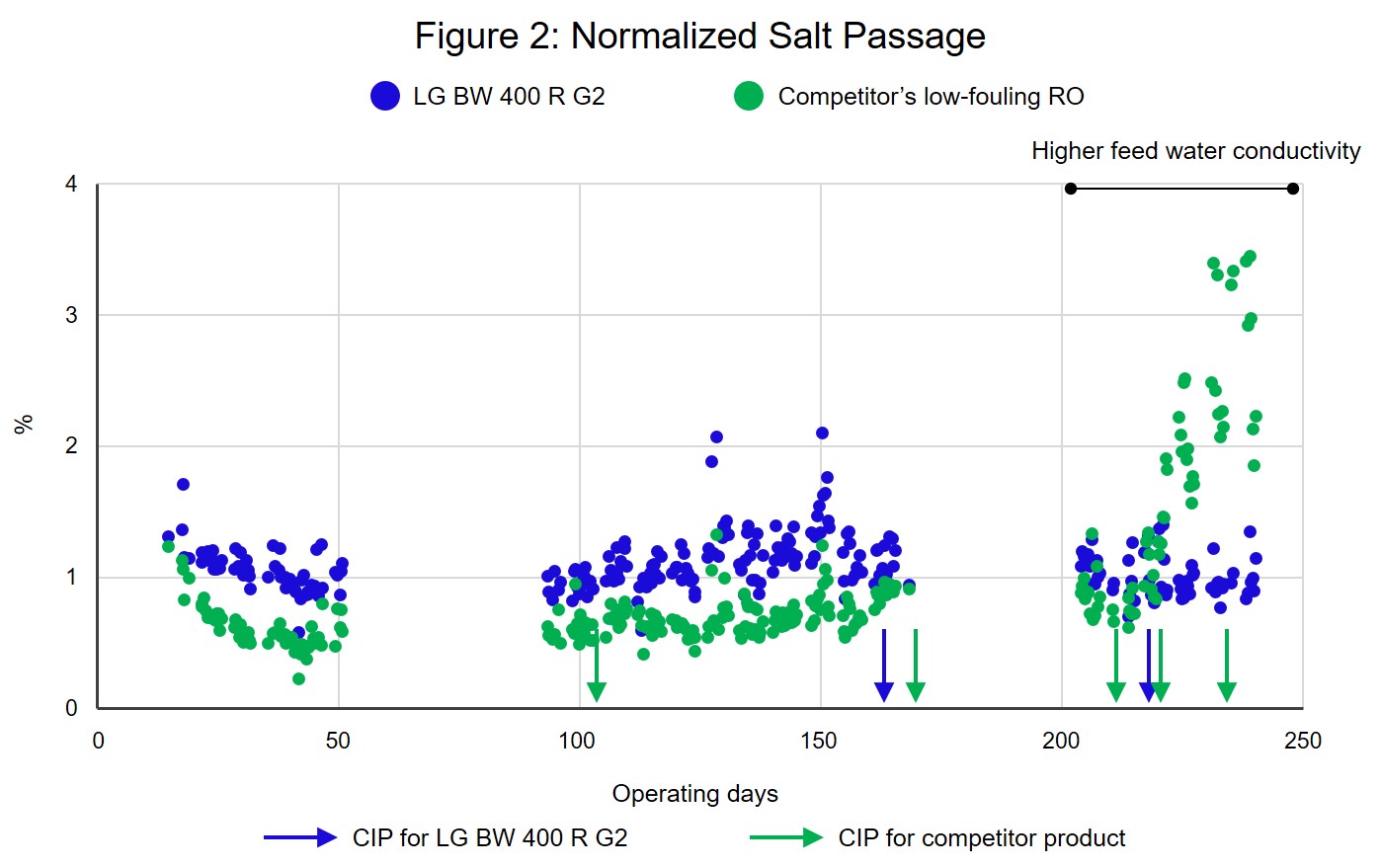

As shown in Figure 1, LG BW 400 R G2 produced a higher specific flux than the competitor model, indicating a lower energy demand for the same amount of water production. The data confirmed more stable salt rejection for LG NanoH₂O™ RO membranes (Figure 2), a critical factor for wastewater applications due to the high fouling tendency of the feed water.

Improved membrane durability and resiliency

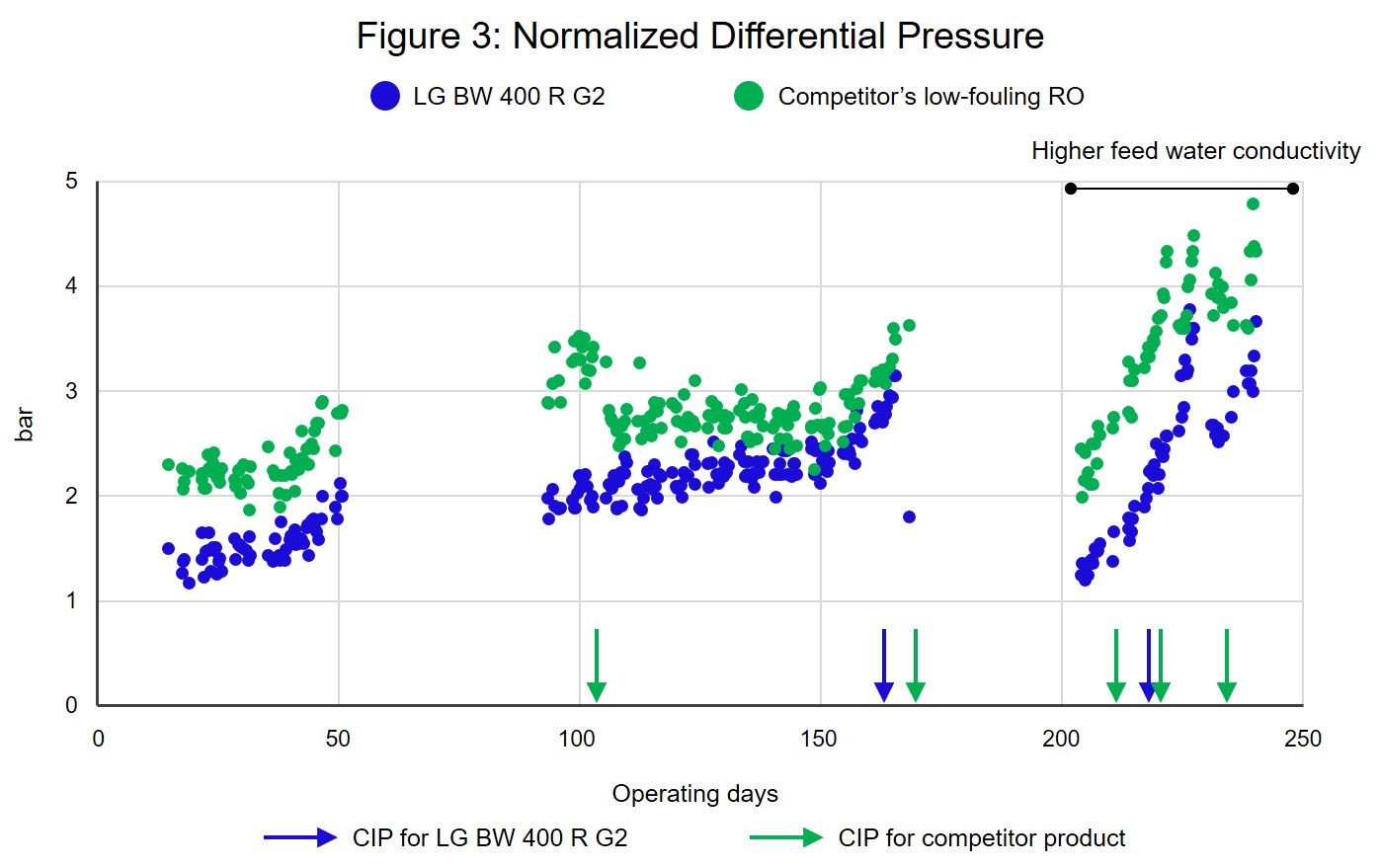

The differential pressure of LG Chem’s product was consistently lower than the competitor’s product, even during a spike in the feedwater conductivity between October and December. Furthermore, the CIP frequency of NanoH₂O™ membranes was remarkably less than half of that required for the competitor’s product (Table 1). These are important indicators of a better fouling resistance and cleanability of LG Chem’s TFN membrane combined with the low dP feed spacer.

| Table 1: CIP History | ||

| CIP number | Competitor | LG BW 400 R G2 |

| 1st | July 17 | Sep 8 |

| 2nd | Sep 9 | Nov 10 |

| 3rd | Nov 6 | |

| 4th | Nov 10 | |

| 5th | Nov 20 |

Outcome

After the trial period, the end-user approved LG NanoH₂O™ RO membranes that successfully demonstrated the following product advantages:

- Higher specific flux: lower energy use without losing permeate quality;

- Excellent membrane durability: better performance recovery after cleanings;

- Robust membrane chemistry: longer and more consistent production of high permeate quality.