Case Study

Background

One of the largest coal-fired plants in North America, located in Georgia, supplies approximately 3,499 mW of power to the northwest communities in the state. The plant uses reverse osmosis as a pretreatment to a two-bed deionization (DI) unit to extend the time between regenerations and provide uninterrupted service. In 2019, the power plant began operating LG Chem’s next-generation and highest rejection BWRO membranes for long-term durability and reliability.

| Table 1: System Information | |

| Feed water | City water |

| Feed water conductivity | 100-110 μS/cm |

| Pre-treatment | Chlorine, UV, Cartridge filters |

| Temperature range | 12–30°C |

| Pilot system design | Two trains of 4:2 (6M) |

| Capacity per train | 681 m3/d (180,000 GPD) |

| System recovery | 75% |

Performance Criteria

LG BW 400 R G2, LG Chem’s highest rejection BWRO membrane element with the new low differential pressure L feed spacer, was installed with the specifications and operating conditions listed in Table 1. The operational requirements of LG NanoH₂O™ RO membranes at the power generation facility can be summarized below:

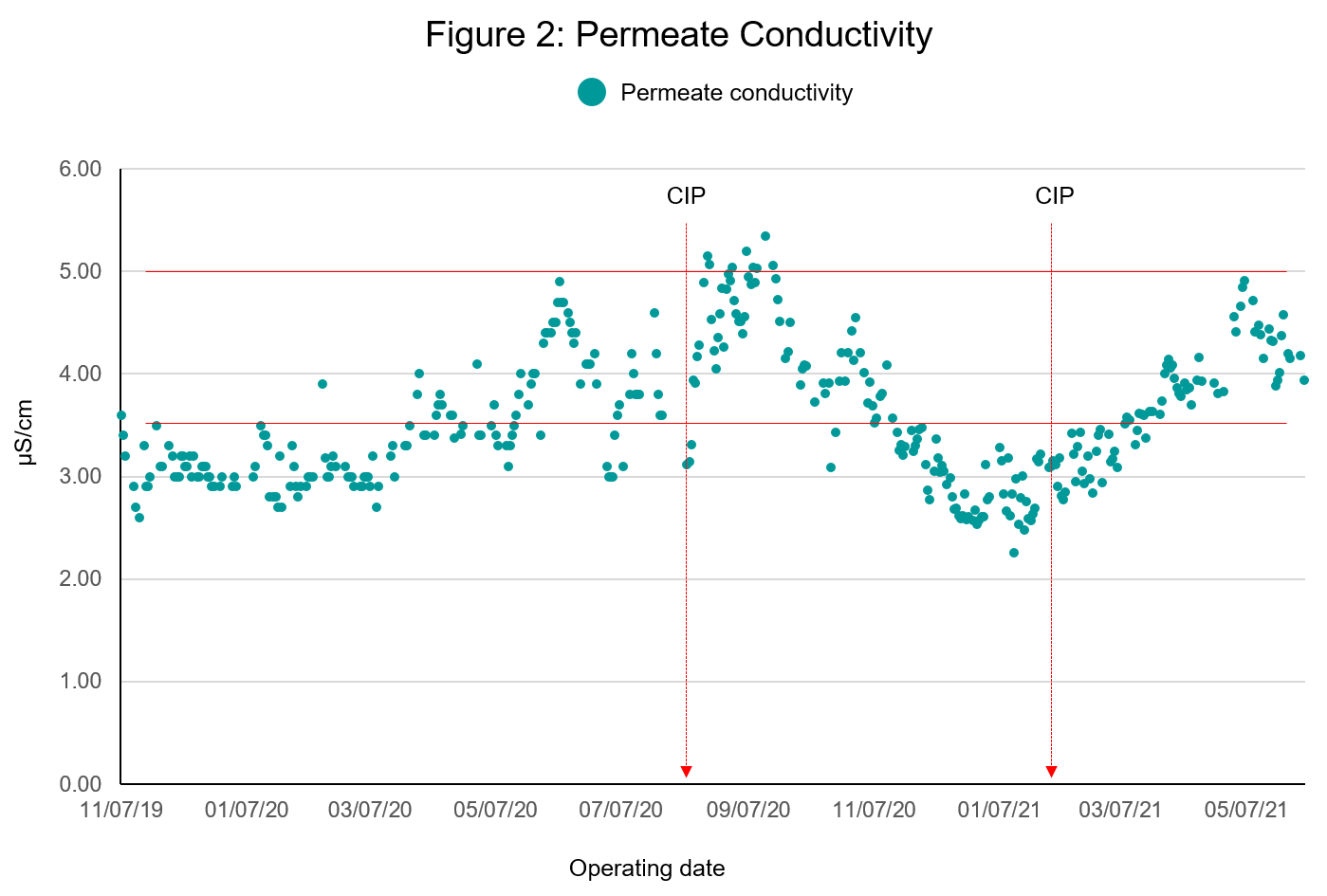

- Maintain permeate conductivity between 3.5 and 5.0 μs/cm, permeate flow rate of 250 gpm per

train, and recovery of 75%; - Demonstrate long-term stable membrane performance after cleaning cycles.

Membrane Performance

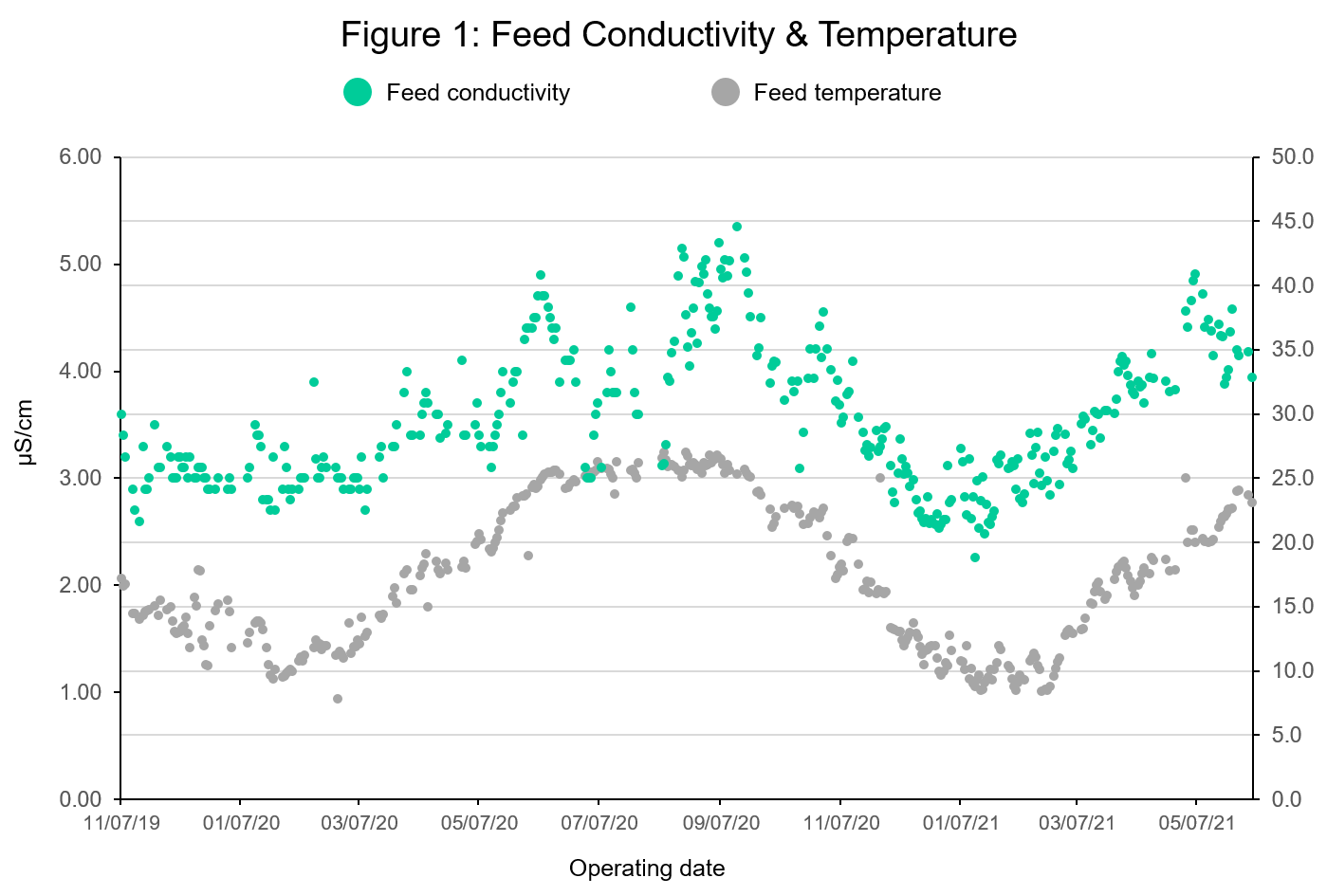

LG BW 400 R G2 has been operating for over 600 days with positive results. As shown in Figure 1, the seasonal temperature variation affected the feed (and permeate) conductivity. However, the permeate conductivity returned

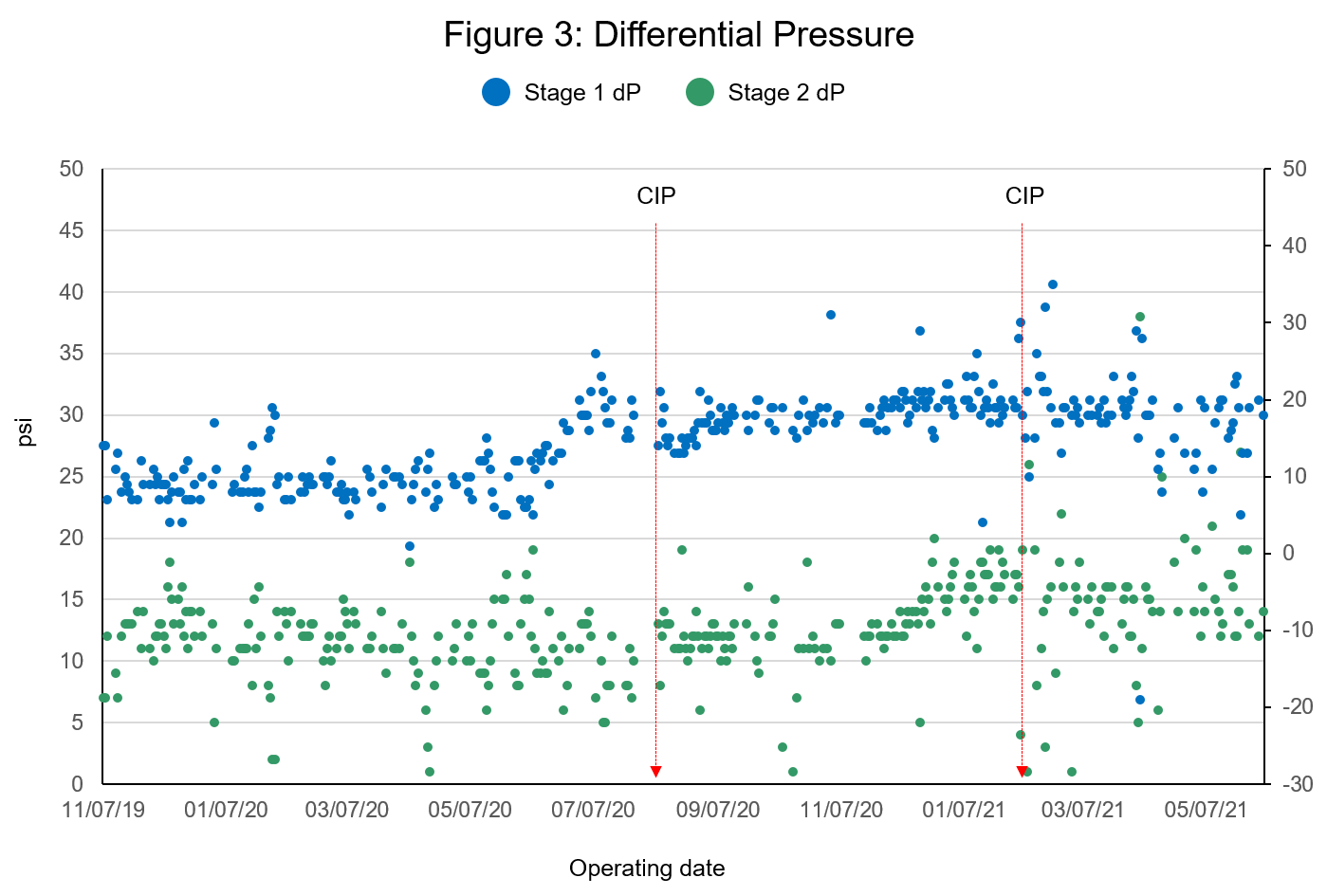

to the required range after each CIP (Figure 2), confirming the robustness of the membrane and minimal impact of cleanings on RO performance. The differential pressure remained stable, indicating a low membrane fouling rate. Only two CIPs were conducted during the operating period, about half the requirement for conventional RO technologies operated at the plant. The plant benefits from the intrinsic anti-fouling properties of TFN membrane technology combined with the low dP feed spacer, which helps to delay fouling and improve cleaning efficiency.

Results

In summary, LG BW 400 R G2 membranes performed better and more reliably than a non-TFN conventional RO membrane for the power generation facility by meeting the following expectations:

- The high standard of permeate water quality required for the boiler feed;

- Good recovery of permeate flow rate and salt rejection after cleanings;

- Low differential pressure indicating a low fouling rate and fewer cleaning requirements.