Case Study

Background

In China, a leading manufacturer of TFT-LCD panels installed LG Chem’s BW 400 ES L energy-saving reverse

osmosis (RO) membrane elements for its ultrapure water (UPW) production process. The plant monitors increases

in differential pressure (dP) for cues in membrane cleaning and TOC rejection as critical parameters for producing high-quality permeate.

System Information

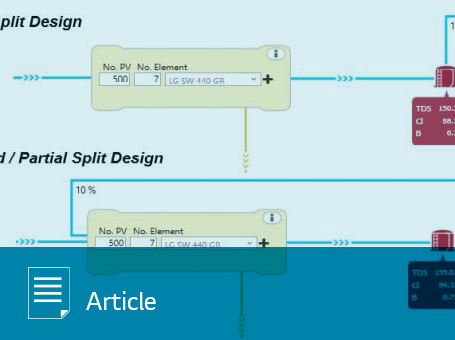

- RO system design: 2 stage, 7:3 array (6M)

- No. of trains: 19

- RO system recovery: 89–90%

- Feed water temperature: 25–26°C

- pH: 7.5–8.5

Novel Feed Spacer

LG BW 400 ES L incorporates a proprietary novel L feed spacer to reduce differential pressure. The result is a lower fouling rate and cleaning frequency, and overall operational cost savings. For more information on the L spacer,

click here.

Membrane Performance

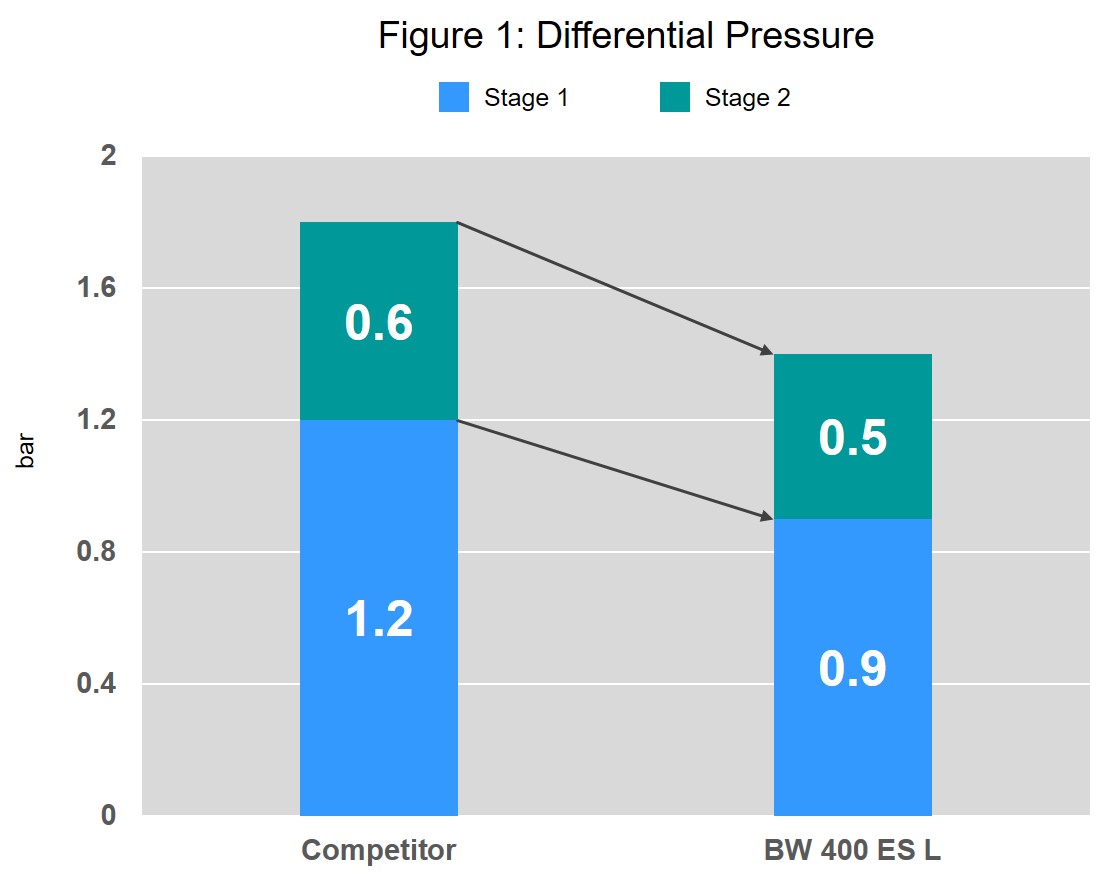

At system start-up, the total differential pressure (1st and 2nd stages) of LG NanoH₂O™ RO elements was about 20% less than the competitor’s equivalent product, also equipped with a factory-supplied low dP feed spacer (Figure 1).

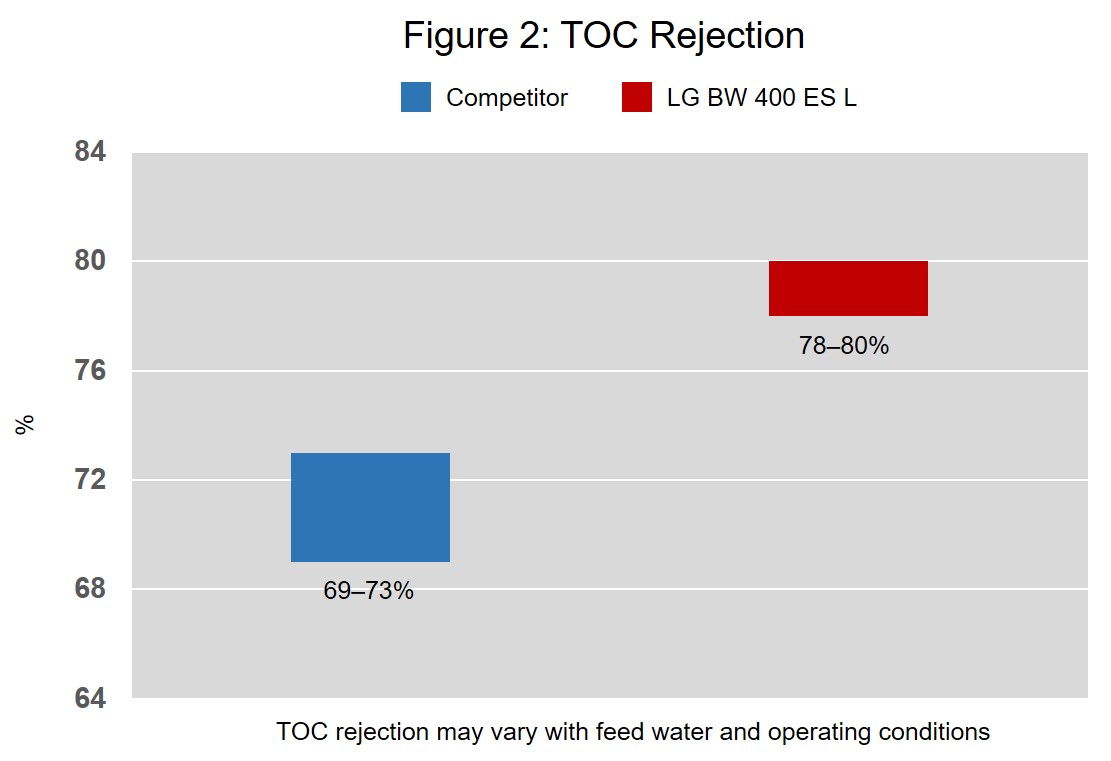

Permeate production was similar for both elements at 80 m³/hr with a 90% recovery rate. TOC rejection for NanoH₂O™ membranes was measured between 78–80%, higher than the competitor model.