Boron is still a challenge in SWRO. Membranes struggle repeatedly to successfully reject it due to its natural state in SW which drives to higher expenses. LG Chem membrane with TFN technology is helping to improve RO performance for boron removal with significant cost savings.

What is Boron?

Boron is the fifth chemical element of the periodic table. It is part of the metalloid group, which consists of elements with properties of both non-metals and metals. It is found concentrated on Earth due to the water solubility of its mineral forms. In water, it is mainly presented in our seawaters around the globe. Its concentration varies depending on the location, with an average value of 4.5 mg/l.

Why is boron controlled in water treatment?

In water treatment, boron is one of the important regulatory concerns for drinking and irrigation water. Boron is a vital element for organic growth, but excessive exposure to it can cause detrimental effects on plants, animals, and potentially humans. Until 2008, the maximum acceptable level of boron in drinking water was set at 0.5 mg/l by World Health Organization (WHO). In 2009, the WHO increased this level to 2.4 mg/l. Despite the WHO boron recommendations, many countries still require a lower maximum concentration. This additional requirement is due to the partial use of potable water for irrigation purposes.

In agriculture, excess boron concentration may cause damage to plants and crops. Although boron is vital as a trace element for plant growth, it can be toxic at higher concentrations. Boron can cause leaf damage, induce premature ripening of certain species and reduce fruit yield.

Why is boron a challenge?

RO membrane technology for dissolved solids separation is based on the polyamide chemistry of an active layer on the membrane surface. Boron in water is found in two different forms, boric acid and borate. The predominant form of boron in seawater is boric acid, which is a small, nonpolar molecule. Unfortunately, polyamide chemistry is not very effective at separating small-size, nonpolar species. On the other hand, the other form of boron found in our seawaters, borate, is negatively charged and is therefore successfully rejected by an RO membrane surface.

Since boric acid is the predominant form of boron in natural conditions in seawater, boron has been a headache for RO membrane manufactures. While rejection of commercial seawater RO membranes is in excess of 99.7% for the majority of ions, rejection of boron is far below that number. Most of commercial SWRO membranes have boron rejection of around 90% or slightly higher. This is typically not enough to meet boron guidelines with a single-pass RO system in those countries where stringent boron regulation is implemented.

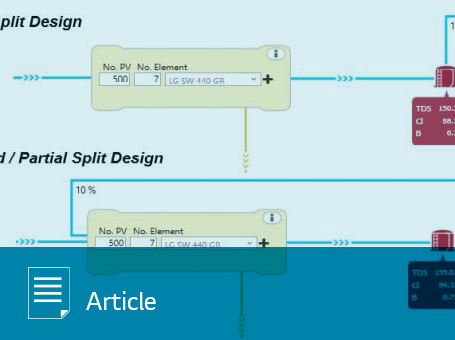

The ratio of boric acid and borate in water can be shifted to one or the other side by operating conditions of an RO system. The two main variables that affect that ratio are feed pH and ionic strength, which is a function of feed salinity. The higher the pH and ionic strength, the higher the fraction of borate present in feed water and, therefore, the more successful removal that can be achieved with reverse osmosis.

In conventional RO systems, improved boron rejection can be achieved by implementing additional passes and polishing steps, which can include pH adjustment. All these measures come at the expense of additional maintenance and increase in both capital and operational costs.

What is TFN technology from LG Chem?

LG Chem NanoH2O™ RO membranes incorporate one of the most revolutionary innovations in desalination technology by embedding nanomaterials into the membrane active layer. This technology is called Thin-Film Nanocomposite (TFN). It was ranked by GWI as the second most breakthrough technology of the past decade. The use of nanocomposite technology has allowed LG Chem to increase membrane salt rejection up to 99.89%, breaking all industry records. Nanocomposite materials allow water to pass through a membrane with lower resistance which helps LG Chem to produce membranes with superior rejection without sacrificing membrane permeability. In addition, TFN membranes have proven to be very efficient in boron removal in many installations around the globe.

Why is boron successfully removed by TFN membranes?

Today, there is not yet a clear answer to that question. While field experience has demonstrated very successful performance of LG Chem TFN membranes with respect to boron removal, the mechanism to explain this phenomenon has not been fully proven yet.

Different theories have been proposed ranging from an interaction between nanomaterials and boron species to the possibility of the higher ionic strength of the feed water along a membrane installation due to extremely high salt rejection. In any case, field evidence reported in many different installations suggests LG Chem TFN membranes should be considered as a clear and safe choice to overcome the issue of boron as they have been able to demonstrate a removal rate per element between 94 and 96% in multiple desalination sites.

Click here to read the full article on Global Water Intelligence.