Case Study

Background

Moss Point, a city in south Mississippi, relies on underground aquifers and wells to supply drinking

water to over 6,000 households and 400 businesses. For decades, the water was treated with

chlorine and safe to drink, but the residents complained of brown coloring and an unpleasant odor

in the water. At that time, the Mississippi Department of Health scored the City’s water two out of

a possible five. As a result, in 2009, the City upgraded its water treatment to incorporate a reverse

osmosis (RO) system, securing a reliable supply of clean water receiving top scores every year since

the installation.

The Moss Point RO system, operated by H2O Innovation, Inc., consists of four skids, each producing

1.25 MGD (4,730 m³/d) of crystal-clear water to the City, removing all impurities, discoloration, and

sulfurous taste. Table 1 below shows additional system information.

“LG NanoH₂O™ membranes are performing very well, and on the

service side, LG has gone above and beyond on many different levels

but primarily by helping us track the data and by letting us know when the

optimum time to clean is.” Samuel Franklin, Plant Manager

| Table 1: RO System Facts | |

| Item | Details |

| Total capacity | 18,920 m3/d (5.0 MGD) |

| Number of trains | 4 |

| Capacity per skid | 4,730 m3/d (1.25 MGD) |

| OEM | H2O Innovation |

| Membrane model | LG BW 400 ES (energy saving model) |

| System design | 24:12 (7M) |

| Number of elements | 1,008 |

| Average flux | 21.3 lmh (12.5 gfd) |

| Recovery | 80% |

Results

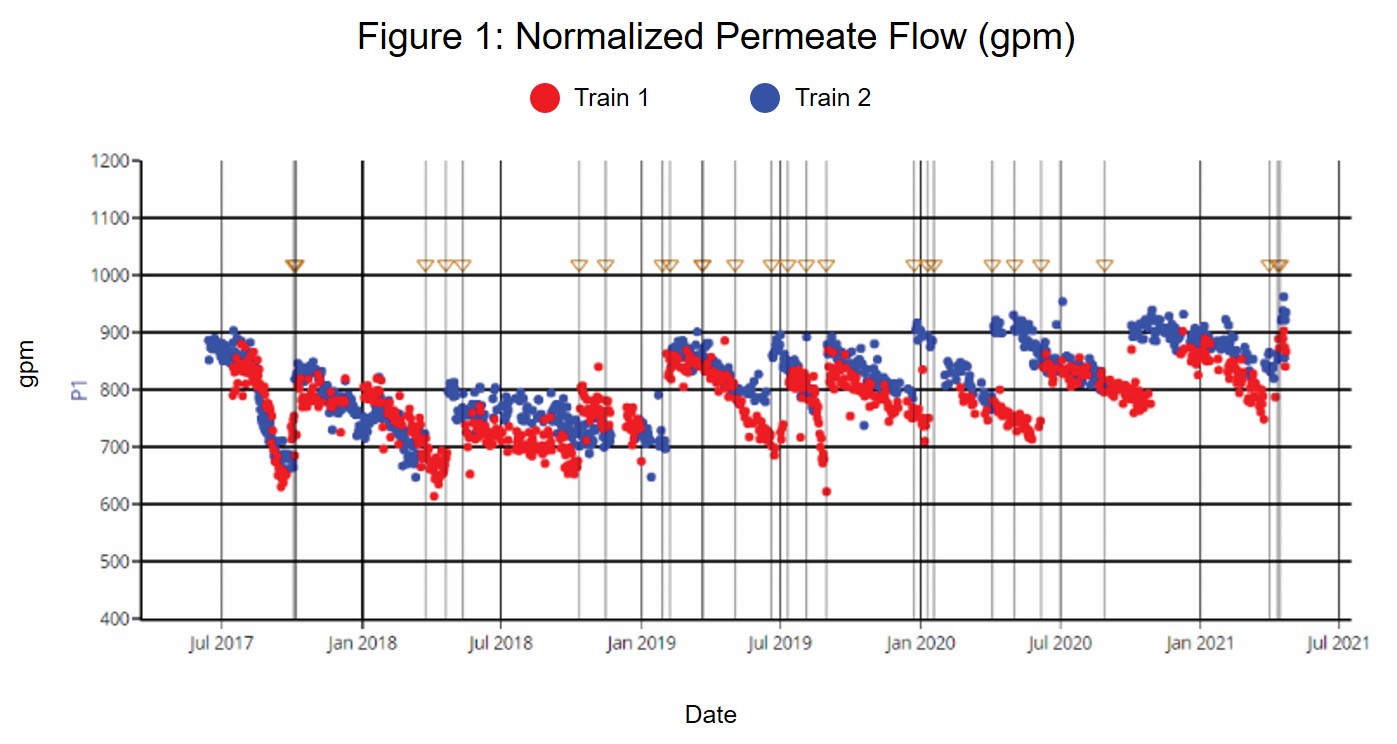

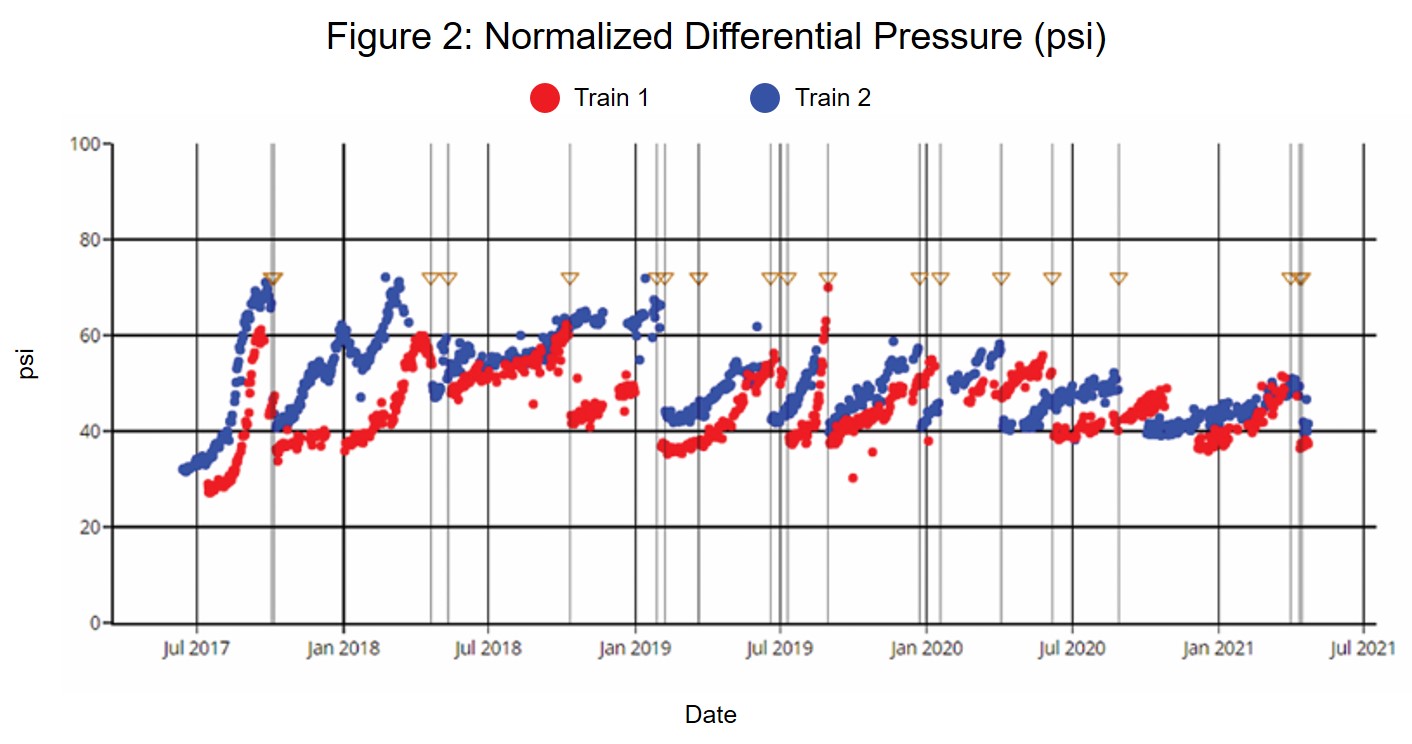

Over the past four years, LG NanoH₂O™ membranes demonstrated solid performance. Figures 1 and 2 show the normalized performance of two out of four trains. Despite high organic content in the well water, which caused rapid fouling and triggered frequent cleanings, the following was observed:

- Normalized permeate flow (Figure 1) recovered well to the original values after each cleaning;

- The normalized differential pressure (Figure 2) also demonstrated good recovery after each CIP;

- Normalized salt passage remained well under control and the membranes are meeting all permeate requirements well below the Maximum Contaminant Levels (Table 2);

- Overall, the membrane performance was very stable and robust after multiple cleaning events.

| Table 2: Annual Drinking Water Quality Report | |||

| Contaminant | Unit | MCL | Final permeate |

| Fluoride | ppm | 4 | ND |

| Chromium | ppm | 0.1 | ND |

| Barium | ppm | 2 | ND |

| Selenium | ppm | 0.05 | ND |

| Lead | mg/L | 0.015 | ND |

| Nitrate | ppm | 10 | ND |

| Nitrite | ppm | 1 | ND |

| Nitrate-Nitrite | ppm | 10 | ND |

| Sodium | ppb | 20,000 | 11,000 |

Outcome

LG Chem’s energy-saving BW 400 ES membranes continue to produce high-quality water at low energy consumption

for many years at the City of Moss Point. The stabilization of performance after cleanings is a strong indication of

membrane reliability and its operation. The City and the RO system have further benefited from the top-notch

operations team of H2O Innovation, providing seamless operation and keeping good data logs, thereby allowing

timely membrane cleanings.